Equipment

| Deutsch |

Apart from our talented researchers, excellent technical equipment is the foundation for successful research. Below you can find the devices available at ZMP.

| Manufacturing | |

|

Arcam A2 – Selective electron beam melting (SEBM) Material development, manufacturing of auxetic structures, basic research |

|

| Arcam Q10 – Selective electron beam melting (SEBM) Selective electron beam melting with narrow beam diameter |

|

| Freemelt One – Open source SEBM system Freely programmable selective electron beam melting machine with an in situ electron-optical process monitoring system |

|

| Estanit – Haage Sheet Former BBS | |

Laboratory scale manufacturing of paper sheets

Stereolithography for manufacturing of three-dimensional objects made from synthetic resin

Laminated Object Manufacturing system for manufacturing of three-dimensional prototypes or parts made from paper, pre-ceramic paper or ceramic green parts. After lamination of each layer, the final shape is generated by laser cutting.

Laminated Object Manufacturing system for manufacturing of three-dimensional prototypes made from paper, pre-ceramic paper or ceramic green parts. After lamination of each layer, the final shape is generated by cutting with a drag-knife.

Vacuum casting system for processing of polymers. Used for example for the infiltration with pre-ceramic polymers.

Generation of interlayers as diffusion barrier in diamond coating

| Ametek – SPECTROMAXx LMM06 | |

Arc spark metal analyzer

Characterization of chirality of carbon nanotubes based on optical spectroscopy

Standard spectrometer for characterization of chemical compounds and layer thickness, including gas measuring cell for coupling with thermogravimetry

Raman microscope for characterization of chemical compounds and nano-scaled objects

Raman microscope with six laser excitation wavelengths for the characterization of chemical compounds and nanoscale objects

Fluoreszens spectrometer for characterization of nano-scaled objects and self-assembly of organic compounds. Two detectors (CCD and IGA) are covering the spectrum from 300 to 1600 nm.

Determination of particle size distribution from 0.01 to 3500 µm

Zeta potential and particle size measurement (DLS) for characterization of colloidal dispersions including automatic titration unit

Optical spectrometer for characterization of chemical compounds and nano-scaled objects

Handheld X-Ray Fluorescent (XRF) Analyzer S1 Titan from Bruker Corporation

Handheld (XRF) analyzer S1 Titan for fast, non-destructive elemental analysis. (Weight: 1.5 kg with battery, Size: 25 × 28 × 9 cm³)

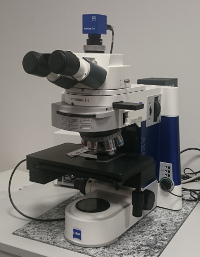

| Carl Zeiss – Axio A1m Imager

Light microscope |

|

| Carl Zeiss – Axio M1m Imager

Light microscope with quantitative image analysis for optical characterization |

|

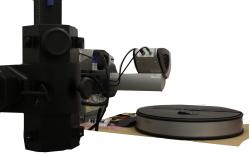

| Carl Zeiss – SteREO

Stereo microscope for three-dimensional surface characterization |

|

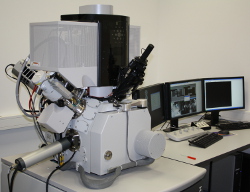

| FEI – Helios NanoLab 600i FIB Workstation

High-resolution scanning electron microscope with field emission source and integrated FIB technique for in-situ sample preparation |

|

| Large-chamber scanning electron microscope

In-situ observation of deformation and failure analysis of large parts |

|

| Olympus – Lext OLS 4000

Laser measuring microscope for contactless surface characterization |

|

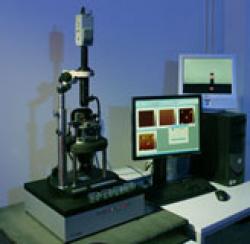

| NT-MDT – Solver Pro SPM Platform

Topological characterization of nano-scaled materials |

|

| Materials Characterization | |

| Fraunhofer Institute EZRT – CT system

Computer tomograph for three dimensional imaging of complex parts |

|

| Fungilab – Premium

Rotational viscometer for determination of viscosity |

|

| Göttfert – RheoTester 2000

Cappilary rheometer for determination of the flow characteristics of materials for powder injection moulding |

|

| Linseis – LFA 1000

Laserflash system for determination of heat and temperature conductivity |

|

| Netzsch – DIL 402 C High temperature dilatometer

Characterization of thermal expansion up to 2000°C |

|

| Netzsch – Skimmer STA 409 CD

Thermo analysis (TG, DSC, DTA) of powders and feedstocks, coupled with mass spectrometry and IR spectrometry (Bruker Tensor27) |

|

| Perkin-Elmer – TGA-MS

Device for thermal analysis (TG, DSC, DTA) of powders and feedstocks, coupled with mass spectrometry and gas chromatography |

|

| Porotec – Pycnomatic ATC Helium pycnometry

Helium pycnometry for determination of closed porosity and true density |

|

| Sigmatest – Creep tester

Characterization of creep properties of metallic compounds |

|

| Steinbichler – 3D digitalizing system

3D scanner for digitalization of complex parts |

|

| Thermo Scientific – Porosimeter Pascal 140/440

Mercury porosimetry for determination of open porosity |

|

| Tropel – Flatness measuring system

Process and quality control of diamond-coated parts |

|

| walter+bai – Rotary bending testing machine

Fatigue strength testing on constant rotating rods |

|

| Thermal Treatments | |

| FCT – Pressure sintering furnace

Hight temperature furnace up to 2500 °C for sintering/graphitation of debindered preforms under pressure up to 100 bar |

|

| Gero – HTK 25 sintering furnace

Sintering of injection mold parts, max. temperature: 1500 °C, atmosphere: high vacuum, argon, nitrogen, hydrogen |

|

|

Gero – GLO 40/11 debinding furnace Thermal debinding of incetion mold parts, max. temperature 1000 °C, atmosphere: argon, nitrogen, hydrogen |

|

|

Gero – LHTM 250/300 vacuum glowing furnace Heat treatment of Fe, Ni and Ti alloys, max. temperature: 1500 °C, atmosphere: high vacuum, argon |

|

| Gero – HTRH 100-300-18

High temperature furnace for sintering of oxidic ceramics in oxidizing atmosphere up to 1750 °C |

|

|

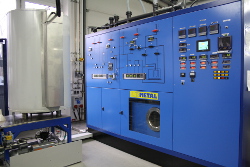

Linn – MFG 180 cold wall induction melting system Melting of alloys with high melting points under inert atmosphere. Power: 180 kW |

|

| MUT – Debinding furnace

Furnace for removal of binder from injection-moulded green bodies |

|

| Nabertherm – HAT 16/17

High temperature furnace for sintering in oxidizing or inert atmosphere up to 1800 °C |

|

| Nabertherm – P330

Muffle furnace for calcination of catalyst materials up to 1100 °C |

|

| Preparative Methods | |

| Beckman-Coulter – Ultracentrifuge

High performance centrifuge for separation of compounds |

|

| CEM – Discover SP

Laboratory microwave for chemical synthesis |

|

| Hermle – Centrifuge Z366

Desktop centrifuge for separation of compounds |

|

| KSV Nima – Minitrough

Langmuir-Blodgett instrumentation for fabrication of monomolecular thin films |

|

| Martin Christ – Freeze drying ALPHA 1-4 LDplus

Universal freeze drying machine |

|

| Metrohm – Karl Fischer 831KF Coulometer

Electrochemical characterization of chemical compounds |

|

| MBraun – MB-Labmaster SP Glovebox

Glovebox providing an inert atmosphere for oxygen and water sensitive reactions |

|

Workstations from Fujitsu and Hewlett Packard:

Processors:

- 2 × Core i5 4950 3.3GHz

- 2 × Xeon E5 1560 3.0 GHz

- 4 × Xeon E5 2630 2.3GHz Turbo-Boost

- 2 × Xeon E5 2630 2.4GHz Turbo-Boost

- 1 × Intel Xeon Phi coprocessor 5110

Memory:

- Abaqus (finite element solver)

- AMPL (optimization tool)

- Aspen (toolbox für process simulation)

- Comsol Multiphysics (modelling software)

- Inventor (CAD software)

- Magics (CAD software)

- Matlab (numerical calculation tool)

- OpenFOAM (CFD simulation tool)